The wet (or viscous) filter makes use of an adhesive in which the dust particles are caught and held upon impingement. It also makes use of densely packed layers of viscous-coated metal baffles, screens, sinuous passages, crimped wire, and glass wool inserted in the path of the air. The air divides into small streams that constantly change their direction and force the heavier dirt particles against the viscous-coated surfaces, where they are held.

The three major types of wet (or viscous) air filters are replaceable, manually cleaned, and automatically cleaned.

Wet replacement type. The glass-wool air filter is of the viscous-type replacement cell. Glass wool, being noncorrosive and nonabsorbing, maintains its density and leaves all the viscous adhesive free to collect and hold dirt and dust. This type of filter lends itself to both small and large installations. A carton of 12 filters weighs about 37 lb. After the filter replacement has been completed, the dirty filters can be put into the original shipping container and removed from the premises.

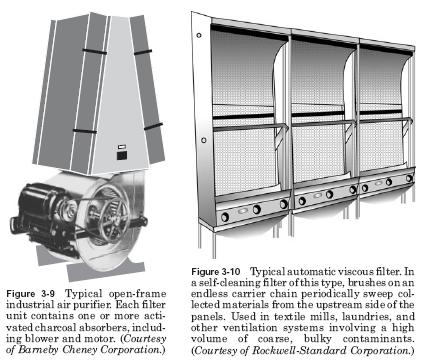

Manually cleaned type. The manually cleaned type is usually made in the form of a standard cell with a steel frame containing the filter media. The cell is fitted into the cell frame ( see Fig. 3-9), with the use of a felt gasket to prevent leakage of air past the cell. As a usual practice, cleaning is necessary about once every eight weeks. This is made a simple matter by the use of automatic latches so that the filter sections can be pulled out of the frame, immersed in a solution of water and washing soda or cleaning compound, allowed to dry, then dipped into charging oil, drained to remove excess oil, and then replaced in the filter.

Automatic viscous filters. The automatic filter is of the self-cleaning type and utilizes the same principle of adhesive dust impingement as the manual and replacement types, but the removal of the accumulated dirt from the filter medium is entirely automatic. The self-cleaning type may be divided into two distinct systems: immersion variety and flushing type.

The immersion-type air filter (Fig. 3-10) makes use of an endless belt that rotates the filter medium and passes it through an oil bath, washing the dirt off. The dirt, being heavier than the oil, settles to the bottom into special containers, which are removed and cleaned from time to time. The usual speed of the filter is from 1.5 to 3 in. every 12 min. Such an apparatus is particularly adapted for continuous operation. The sediment can be removed and the oil changed or added without stopping the apparatus.

The flushing type is constructed of cells in the form of a unit laid on shelves and connected by metal aprons. The dirt caught by the cells is flushed down into a sediment tank by flooding pipes, which travel back and forth over the clean-air side of the cells. Aprons catch the heavier dust particles before they get to the cells so that the cells are more efficient. This type does not flush the cells while the system is in operation. In many cases, duplicate units are provided so that one unit can be flushed while the other bears the full load. Some of the flushing mechanisms are interlocked with the fan circuit, especially where a single unit is used, so that flushing cannot take place unless the fan is shut down. If air is permitted to pass through the filter while it is being flushed, oil will be carried along with the air.

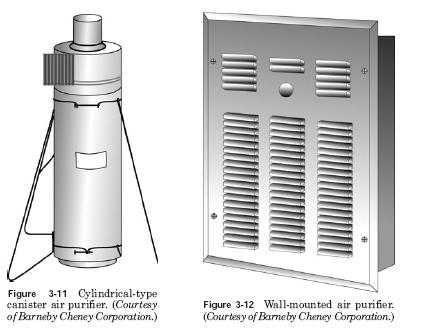

Acylindrical absorber (shown in Fig. 3-11) can be used for the control of odor problems by forcing air through two perforated metal walls enclosing an annular bed of activated charcoal. Amotor-operated blower draws contaminated air through the charcoal-filled container and recirculates pure odor-free air through the room or space to be purified.

The wall-mounted air purifier shown in Fig. 3-12 is equipped with a washable dust filter and centrifugal blower. Air purifiers of this type are ideal for toilets, utility rooms, public rest rooms, and similar odorproblem areas.

In residential-type air conditioners, however, unit filters provide the necessary dust protection, particularly since they are manufactured in a large variety of types and sizes. Where lint in a dry state predominates, a dry filter is preferable because of its lint-holding capacity. Throwaway filters are used increasingly where the cleaning process needs to be eliminated.