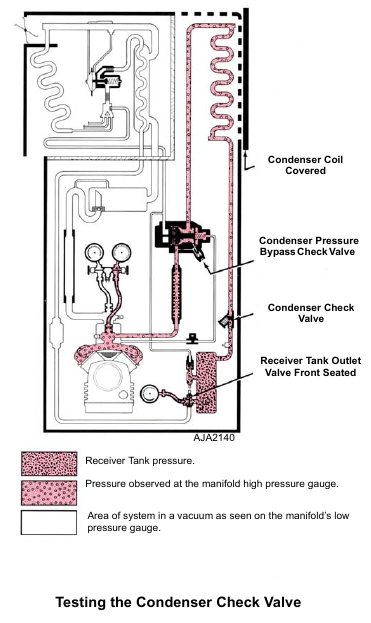

1. Front seat the condenser pressure bypass check valve.

2. Operate the unit in high speed cool and cover the condenser coil to build discharge pressure:

• R-12, R-401B and R-134a = 250 to 250 psig

• R-502, R-22, R-402A, R-403B and R-404A = 300 to 350 psig

3. Pump down the low side, while keeping the condenser coil covered.

4. When discharge pressure begins to decrease and the low pressure gauge reaches a 10 inch vacuum, remove the condenser cover to reduce discharge pressure approximately 100 psig. STOP THE UNIT.

5. Observe the manifold high pressure gauge:

• a pressure increase – indicates the condenser check valve leaks.

• receiver tank pressure must remain above condenser pressure – indicating a good condenser check valve.

NOTE: Receiver tank pressure may decrease slowly but must remain higher than the gauge manifold’s high pressure.