Lines and hoses are used to connect the main components of the AC system together. The lines are typically made from aluminum and the hoses are made from multilayered flexible rubber that is reinforced with nylon. The hoses used on newer-model cars and trucks are much higher quality than those used in the early days of AC-equipped cars and trucks.

Many lines and hoses are held in place with brackets and clips that prevent them from rubbing against another component. It is important to reinstall these items when replacing the lines or hoses to ensure that the repair will be of high quality. Below are some key points to follow when replacing lines and hoses.

Use the following steps when servicing bolted connection–style lines and hoses.

Bolted Connections

1. Inspect the connection to determine the correct size wrench or socket to use when loosening the connection. It is preferable to use the exact size wrenches when loosening and tightening these connections to prevent damaging the hex corners of the fasteners. If a socket is the tool of choice, then use a six point–style socket.

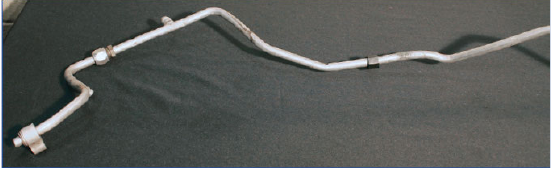

Aluminum lines are used to connect the AC components together. Care should be taken when working around these lines to keep from bending or damaging them, which would cause a

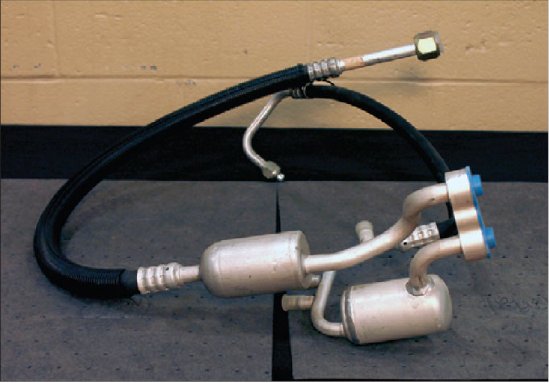

Line and hose assemblies are used in many parts of the AC system to connect the system. These assemblies will be made of aluminum as well as being connected with factory crimps to flexible rubber hoses. The hoses used on these systems are multilayered and provide excellent integrity to prevent refrigerant

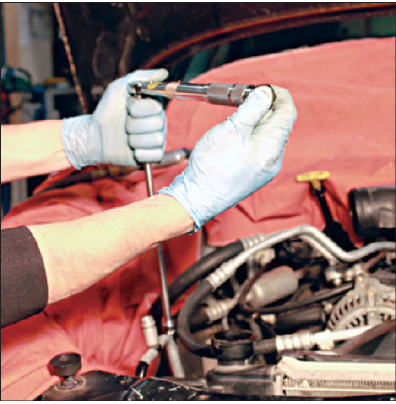

Two wrenches are needed to service the bolted connections on refrigerant lines. The exact size should be used when loosening and tightening these connections to prevent rounding the corners of the hex-shaped fittings. The O-rings should always be replaced when opening up connections in the AC

2. Finish loosening the connection by rotating the fasteners by hand.

3. If replacing the line or hose, be sure that new gaskets and/or O-rings are used in every location that is opened during the repair. See the instructions following this for information on the service procedures.

4. Carefully start the assembly of the fasteners by hand by rotating them clockwise. Be sure that the fasteners start perfectly by rotating them by hand two or three revolutions before using tools to finish the tightening procedure.

5. Finish the tightening procedure by using a torque wrench where possible to bring the tightness of the connection to the exact level. Refer to a reliable service source to find the torque specification.

It is wise to use flare nut wrenches on AC lines whenever possible to prevent rounding the corners of the hex-shaped nuts. These tools provide more contact with the surface than standard open-end

Extra care should be practiced when starting to connect two sections of line together to prevent damaging the threads on the fasteners. It is wise to turn the fasteners by hand two or three turns before using

A torque wrench should always be used to ensure that the fasteners are correctly tightened. A connection that is too loose will leak and a connection that is too tight will likely damage the threads. The correct torque should be researched from a reliable