Use the following procedures when servicing ball-style valves.

1. Remove the plastic cap to determine the size and the style of valve that is used.

The ball-type check valve assembly fastens to the line using a threaded connection. When this valve requires service, it is replaced as an assembly. Always install the plastic cap when the repair is completed to help keep debris out of the fitting. The cap also serves as a secondary leak deterrent for the

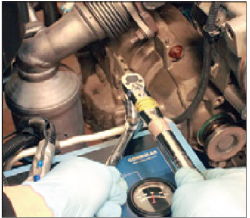

2. Choose the correct size wrench or socket that fits the hex-shaped valve. It is advisable to use six-point tools to prevent rounding the corners on the valve.

3. Choose the correct size of wrench to hold the base of the line or component to assist in breaking the connection loose.

The ball-style check valve is removed with sockets and wrenches as an assembly. This fitting is typically very tight and takes a considerable amount of twisting to break the connection loose, so the correct size tools should be chosen and

4. Carefully turn the tools counterclockwise to remove the valve.

5. Choose the correct size of replacement valve.

6. Install a new O-ring along with a little refrigerant oil.

Refrigerant oil should be added to the O-ring on the new valve prior to

installing it on the vehicle. The oil helps the O-ring seal and provide

good leak prevention for the

7. Carefully start the new valve by turning it clockwise by hand.

The new ball-style check valve is reinstalled by carefully turning clockwise to engage the threads without cross threading the connection. The new valve should be turned two or three turns before using tools to finish the

8. Use a torque wrench to bring the tightness to the specified level. The torque value for these valves are 7 to 10 ft-lbs for the high side and 5 to 7 ft-lbs for the low side.

A torque wrench should be used to finish tightening the ball-style check valve to ensure that the unit is installed at the correct tightness. If this repair is left too loose, the system will likely leak, and if the fitting is tightened too tight, the threads could be