DBVs provide an economical method of compressor capacity control in place of cylinder unloaders or of handling unloading requirements below the last step of cylinder unloading.

On air-conditioning systems, the minimum allowable evaporating temperature that will avoid coil icing depends on evaporator design. The amount of air passing over the coil also determines the allowable evaporator minimum temperature. The refrigerant temperature may be below 32°F (0°C). However, coil icing will not usually occur with high air velocities, since the external-surface temperature of the tube will be above 32°F (0°C). For most air-conditioning systems the minimum evaporating temperature should be 26 to 28°F (?3.3 to ?2.2°C). DBVs are set in the factory. They start to open at an evaporating pressure equivalent to 32°F (0°C) saturation temperature. Therefore, evaporating temperature of 26°F (?3.3°C) is their rated capacity. However, since they are adjustable, these valves can be set to open at a higher evaporating temperature.

On refrigeration systems, discharge-bypass valves are used to prevent the suction pressure from going below the minimum value recommended by the compressor manufacturer. A typical application would be a low temperature compressor designed for operation at a minimum evaporating temperature on Refrigerant 22 of ?40°F (?40°C). The required evaporating temperature at normal load conditions is ?30°F (?34°C). A discharge-bypass valve would be selected that would start to open at the pressure equivalent to ?34°F (?36°C) and bypass enough hot gas at ?40°F (?40°C) to prevent a further decrease in suction pressure. Valve settings are according to manufacturer’s recommendations.

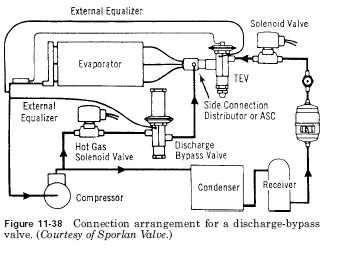

The discharge-bypass valve is applied in a branch line off the discharge line as close to the compressor as possible. The bypassed vapor can enter the low side at one of the following locations:

? To evaporator inlet with distributor

? To evaporator inlet without distributor

? To suction line

Figure 11-38 shows the bypass to evaporator inlet with a distributor. The primary advantage of this method is that the system thermostatic expansion valve will respond to the increased superheat of the vapor leaving the evaporator and will provide the liquid required for desuper heating. The evaporator also serves as an excellent mixing chamber for the bypassed hot gas and the liquid-vapor mixture from the expansion valve. This ensures that dry vapor reaches the compressor suction. Oil return from the evaporator is also improved, since the velocity in the evaporator is kept high by the hot gas.

Excusme.lwant to know how work bypass valve with pressure pilot.

Tankyou